Assistance with product selection, contract work and repairs

As an expert for heat treatment equipment and at the same time user of furnaces from our own production, HTM REETZ offers various services.

We will be happy to advise you on the selection of your product and provide a repair service for HTM equipment, and if feasible, also for third-party products.

Of course, we also accept your orders for work in equipment from our technical centre.

We are also happy to support you with questions regarding the feasibility of special heat treatments and the charging of furnaces.

1. Advice

Our experienced staff will advise you personally:

- in the selection of a furnace or plant suitable for your requirements

- with the implementation of your task in a unique equipment, if necessary

- when defining the required parameter field

- in the selection of the appropriate accessories

In particular, you will find competent answers to questions about material compatibility in the high temperature range and material selection.

2. Pilot plant and contract work

For the thermal treatment of development batches, both furnaces of our in-house pilot plant station and rental equipment are available.

We will be pleased to accept your commissioned work by arrangement.

In particular, we have the technical facilities for work in the following areas:

Tempering in air

- Maximum temperature 1600 °C,

- Available furnace chamber: max. 400 x 1500 x 350 mm³

- Maximum temperature 1750 °C,

- Available furnace chamber: max. Ø 50 mm, height: 200 mm

Tempering in oxygen-free atmosphere or hydrogen

- Maximum temperature 1800 °C,

- Available furnace chamber: max. Ø 260 mm, height: 300 mm

Vacuum tempering

- P < 1 x 10-5 mbar,

- Maximum temperature 1200 °C,

- Available furnace chamber: max. Ø 150 mm, height: 300 mm

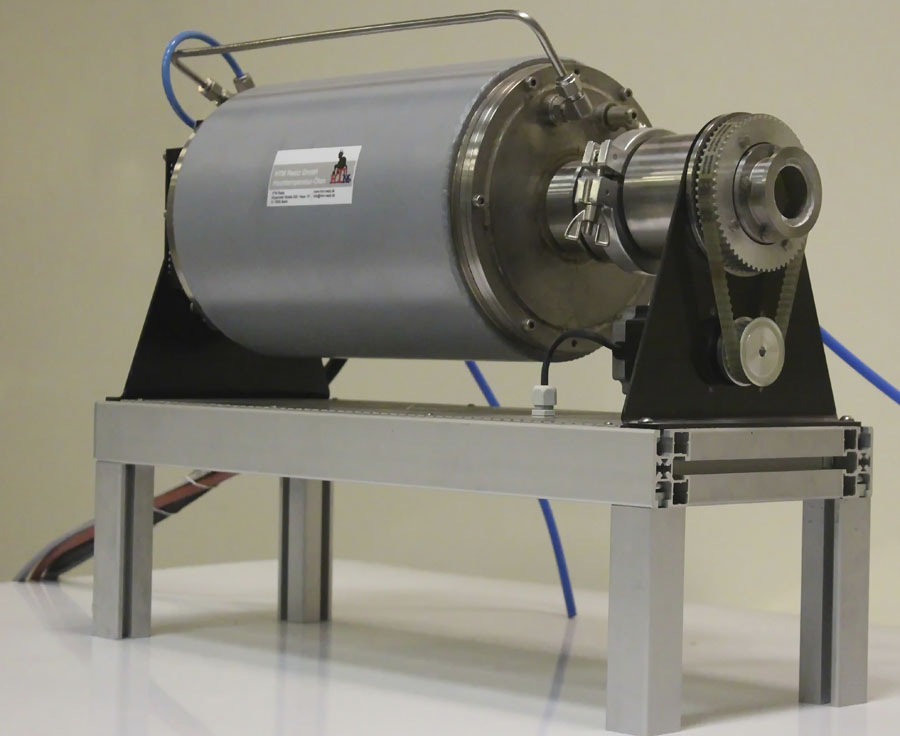

Tempering of bulk materials

- To air in the rotary furnace (continuous operation)

- Maximum temperature: 1100 °C,

- Transportability of the bulk material must be checked;

- In oxygen-free atmosphere in the rotary furnace (continuous operation),

- Maximum temperature: 1100 °C,

- Transportability of the bulk material must be checked;

- In air, inert and reducing atmosphere in rotating ampoule,

- Maximum temperature: 1750 °C,

- Available furnace chamber: max. Ø 50 mm, height: 200 mm

Brazing of metal-ceramic pairings

according to the active metal soldering technique

- Including advice on the material combinations and the ceramic-compatible design of the soldered connection

3. Repair service and modernisation

As a competent partner for high-temperature technology, we offer you a comprehensive service when it comes to the repair, modernisation or inspection of products manufactured by HTM REETZ. By arrangement, we can also provide you with systems from other manufacturers.