Cold wall furnaces / Vacuum furnaces

Cold wall furnaces or vacuum furnaces are furnaces in which a gas-tight, pressure-resistant housing encloses the heating conductor and working chamber, while at the same time the wall is cooled to ensure the strength.

Usually these are vacuum or high-pressure furnaces with heaters made of graphite or refractory metals such as tungsten or molybdenum. Tube furnaces of type LORA-G can also be assigned to this furnace class.

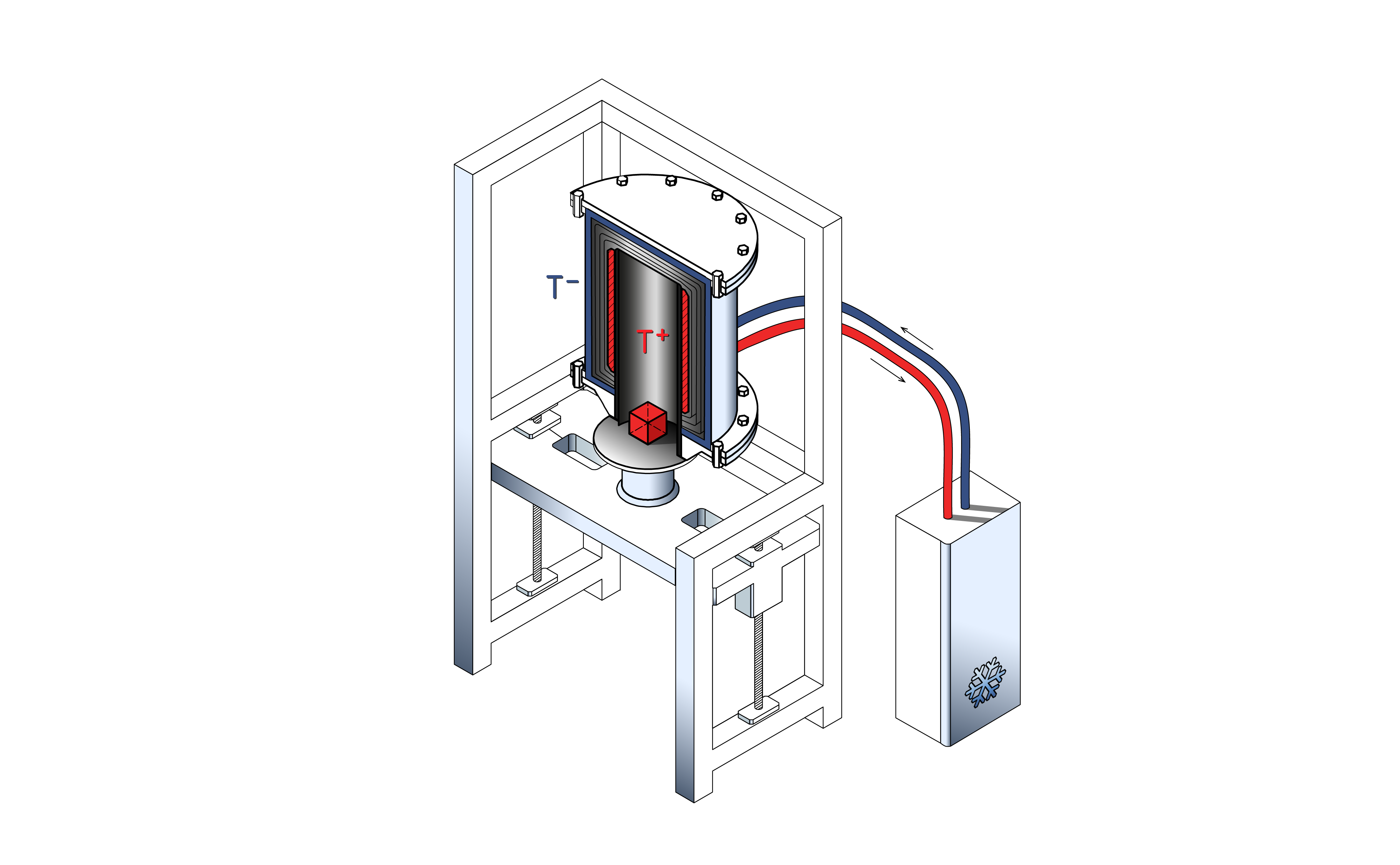

Cold wall high vacuum furnaces with tungsten heater

Thanks to the exclusive use of shielding plates for thermal insulation and ventilation with dry inert gas, cold-wall high-vacuum furnaces with tungsten heaters are characterized by good vacuum, short pump-down times and fast cooling times.

Short description:

- Temperatures up to 2500 °C

- Atmospheres: inert or vacuum

- Working area diameter: approx. 100 to 300 mm

- Heated height: 200 to 400 mm

- Achievable pressure: 1 x 10-6 mbar

- Power range: 10 to 100 kW

- Temperature measurement with pyrometer or thermocouple type C (up to 2200 °C

Heating system:

- Single-zoned

Charging:

- Top loader

- Lift-bottom furnaces

Equipment features:

- Complex control unit with PC interface for furnace,

vacuum generation, inert gas inlet and sample movement - Software for control unit

- Movable sample thermocouples

- Observation window

- Crucibles and boats

- Rotating sample stages

- Protective gas system with pressure relief valve for operation as

protective gas furnace

Applications:

- Physical experiments

- Solid state chemical analyses

- Melting/alloys

- Sintering

- Recrystallization (W-coils in lamp production)

- Vacuum tempering

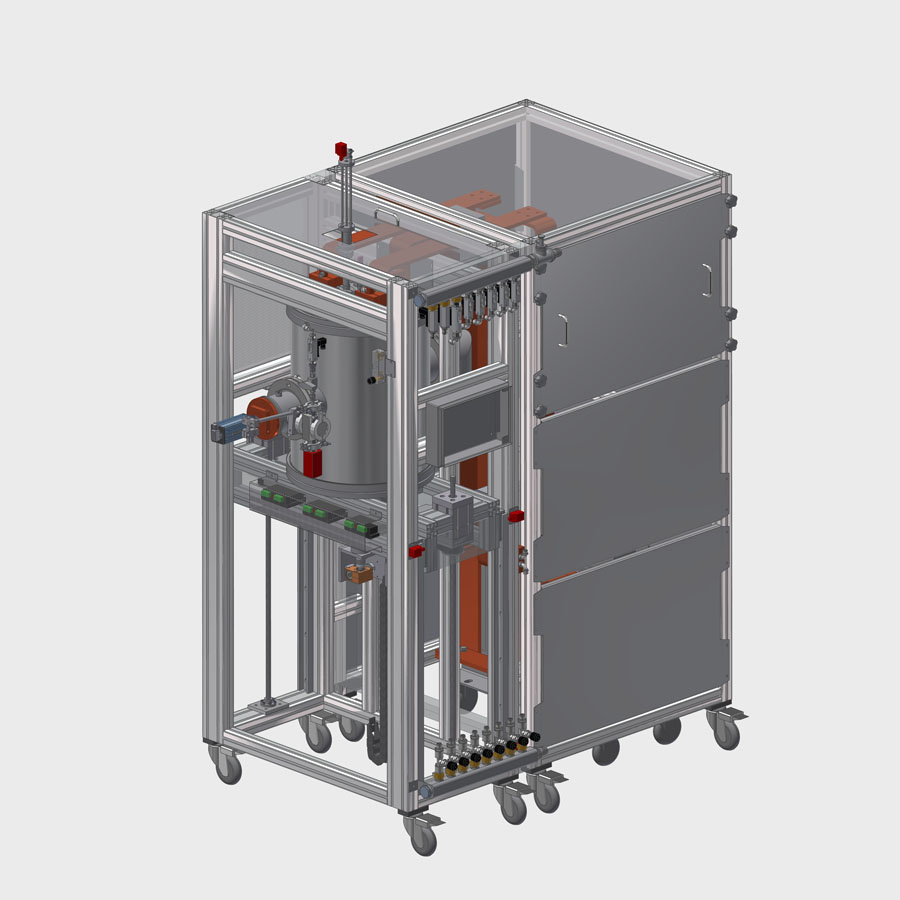

Cold wall high pressure furnaces

The furnace type cold wall high pressure furnace combines a pressure-resistant cooled wall with a metal heater. Materials are used for insulation, which make heat exchange by convection particularly difficult.

Short description:

- Temperatures up to 1800 °C

- Atmospheres: depending on the heater used

- Working area diameter: 40 to 100 mm

- Heated height: 200 to 2000 mm

- Achievable pressure: 100 bar

- Power range: 10 to 100 kW

- Temperature measurement with thermocouple

Heating system:

- Single-zoned

- Multi-zoned

Charging:

- Top loader

- Lift-bottom furnaces

Equipment features:

- Wide range of control units with and without PC interfaces

- Software for control unit

- Crucible

- Movable sample thermocouples

- Feeding device with gravimetric dosing

- Quenching device

- Additional working tubes

Applications:

- Melting/alloys

- Pressure sintering

- Investigation of the reaction kinetics at high

temperatures and pressures